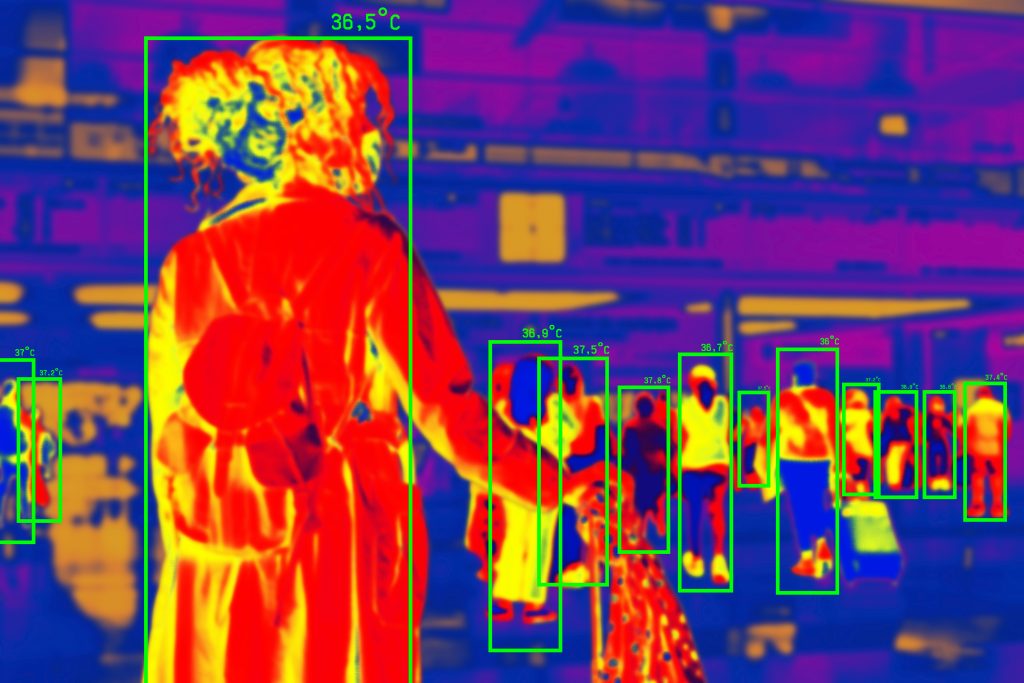

CAE (Computer Aided Engineering)

CAE (Computer Aided Engineering) is the most important step towards any product development, as we know most of the aerospace and automotive OEM and tier suppliers are focused on CAE as need of more precision in these industries to check product reliability & product life cycle to reduce time as well as cost. Here we help customers in complete product development with our unique blended approach where our CAE expertise establishes interface between simulation and CAD model during design phase by giving exact result make them to predict the product performance in-order to test before creating a physical prototype leading to save manufacturing cost & time. CADELL has the team of CAE expertise who has hand-on experience on multiple tools like ANSYS NASTRAN ADAMS LS-Dyna & HYPERMESH.

Engineering Analysis and Simulation (CAE)

CADELL Capabilities on CAE (Computer Aided Engineering):

CAE (Computer-Aide-Engineering) is the most important step towards any product development, as we know most of the aerospace and automotive OEM and tier suppliers are focused on CAE as need of more precision in this industry to check product reliability product life cycle to reduce time as well as cost. Here CADELL helps customers in complete product development with our unique blended approach where our CAE expertise establishes interface between simulation and CAD model during design phase by giving exact result make them to predict the product performance in order to test before creating a physical prototype leading to save manufacturing cost. Cadell have team of CAE expertise who has hand-on experience on multiple tools like ANSYS NASTRAN ADAMS LS-Dyna & HYPERMESH.